Sewage Treatment Plant: STP Plant Manufacturers

Sewage Treatment Plant: STP Plant Manufacturers, Supply, Erection, on a turnkey basis for various types and natures of Sewage Treatment Plant, Supply, Erection of Sewage Treatment Plant (STP Plant) on a turnkey basis for various types and natures of sewage water.

Sewage is the waste induced by residential, commercial, and industrial institutions. STP works treat the sewage to construct it for secure disposal, agricultural use, or domestic use in washrooms, etc.

Sewage usually includes a heightened amount of organic and inorganic waste. It is required to treat sewage before it enters any water body. Suppose sewage is allowed to enter the water sources without treatment.

In that case, it will contaminate them, so it is essential to treat sewage properly before letting it into rivers or other water sources.

Sewage Treatment Plant Inquiry!

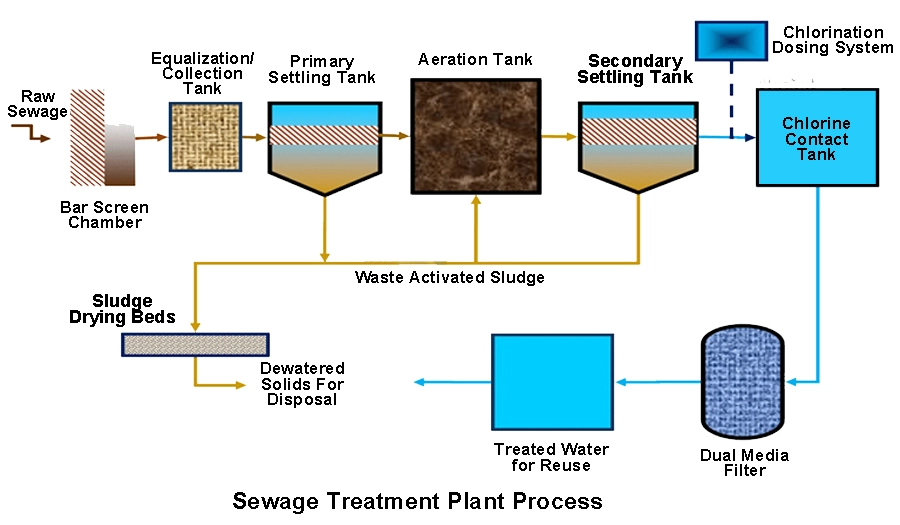

Sewage Treatment Plant flow sheet diagram: STP Continuous Type

- Bar Screening:

- In the sewage treatment plant, water passes through a bar screen to remove all large objects like cans, rags, sticks, plastic packets, etc., carried in the sewage stream.

- Grit Removal:

- Reduce the formation of deposits in primary sedimentation tanks, aeration tanks, anaerobic digesters, pipes, channels, etc.

- Reduce the frequency of tank cleaning caused by excessive accumulation of grit.

- Protect moving motorized equipment from abrasion and attending abnormal wear.

- Flow Equalization Tank:

- Fat and grease removal:

- Primary treatment:

- Secondary Treatment:

- Tertiary treatment:

- Sludge treatment and disposal:

Primary treatment: Horizontal flow grit chambers at a sewage treatment plant in grit consists of sand, stone, rocks, and additional weighty materials. Immediate treatment may contain a sand or grit removal channel or chamber. Grit removal is necessary to:

Grit removal is essential for equipment with closely machined metal surfaces, such as comminutors, fine screens, centrifuges, heat exchangers, and high-pressure diaphragm pumps.

Equalization inlets achieve flow equalization to reduce peak dry-weather flows or peak wet-weather flows in the case of combined sewer systems. The benefits are performance improvements in the biological treatment processes, the secondary clarifiers, and filtration equipment.

In some larger plants, fat and grease pass the sewage through a small tank where skimmers collect the fat floating on the surface. Air blowers in the tank's base may also help recover the fat as a froth. Many plants use primary clarifiers with mechanical surface skimmers for fat and grease removal.

Primary treatment is the "reduction of an amount of the suspended solids and organic matter from the sewage." It allows sewage to pass via an inlet where rich solids can settle to the base while lubricant, grease, and soft solids flow to the surface and skim off. These bases are called "primary sedimentation tanks" or "primary clarifiers" and typically have a hydraulic retention time (HRT) of 1.5 to 2.5 hours. The rigid and floating materials remove, and the remaining liquid may be discharged or subjected to secondary treatment. Preparatory settling tanks are usually equipped with mechanically moved scrapers that continuously drive the collected sludge toward a hopper in the tank's base, pumped to sludge treatment facilities.

The main processes in secondary treatment remove as much substantial material as possible. They use biological processes to recapitulate and clear the remaining soluble material, especially the organic fraction. This process suspends growth or biofilm procedures. The microorganisms that forage on the organic matter present in the sewage grow and multiply, constituting biological solids or biomass. These products and groups are in the form of flocs or biofilms and granules in some specific processes. In several treatment processes, the biological floc or biofilm and remaining fine solids can then be settled as sludge, leaving a liquid substantially free of solids and a significantly reduced concentration of pollutants.

Advanced sewage treatment generally involves three main stages: primary, secondary, and tertiary treatment but may also include intermediate steps and final polishing processes. The tertiary treatment (also called "advanced treatment") is to provide a final treatment stage to improve the effluent quality further before it is discharged to the receiving water body or reused. It is always the final process.

Sludge is especially water with some quantities of stable material extracted from fluid sewage. Primary sludge contains settleable solids released during immediate treatment in prior clarifiers. Secondary sludge is sludge separated in secondary clarifiers that are operated in secondary treatment bioreactors or processes using inorganic oxidizing agents. In intensive sewage treatment processes, the sludge produced needs to be removed from the liquid line continuously because the volumes of tanks in the fluid line have the insufficient volume to store sludge.

Gaurav Water Solution is one of the best Sewage treatment Plant manufacturers in Bharat and across the globe. Please contact us now at 9211627332.Questionnaires for designing proper solution in Sewage Treatment Plant (STP Plant):

| # | Description |

|---|---|

| 1 | Name of the Party with detailed Office / Factory address with the concerned person name and contact nos? |

| 2 | The site address in detail where this plant is going to Install / Operate? |

| 3 | Are you an end-user of this project? |

| 4 | What is the primary purpose of installing the system - Govt regulation / Strong need for recycling / To get PCB consent / Caring environment? |

| 5 | What is your manufacturing activity/process (Pls attach a flowsheet diagram showing wastewater generating stations)? |

| 6 | Sewage Composition (i.e., what will be the specific contents of Sewage)? |

| 7 | Approx Total quantity of Sewage generated daily? |

| 8 | New project or modifications, Please provide details about the existing system as - Pictures, Capacity, BOQ, etc. |

| 9 | Please attach a detailed Sewage analysis report comprised of pH, TDS, TSS, COD, BOD, O&G, Cl, SO4, etc.? |

| 10 | Did output treat water quality expected - In terms of parameters as mentioned above? |

| 11 | Should you carry out any treatability studies for Sewage? If so, please attach the report herewith. |

| 12 | Location availability - Allocated area in terms of L X W X H in Meter? |

| 13 | Types of System: Civil / Containerised / MS-Package? |

| 14 | Output Treated Water Quality in terms of TSS & BOD (Or attach specific requirement) |

| 15 | Final usage of treated Water - Gardening / Toilet Flushing? |

| 16 | Do you have your own civil construction contractor/team? |

| 17 | When are you expecting to start this project date? |