ETP Plant: Effluent Treatment Plant Manufacturers in Delhi NCR

We are the Manufacture, Supply, Erection of Effluent Treatment Plant (ETP Plant) on a turnkey basis for various types and natures of wastewater.

Effluents combine advanced Physico-chemical treatment and biological treatment processes with a tertiary polishing system to remove organic, inorganic, oil and grease, heavy metals & suspended solids.

Effluent is generating in many manufacturing enterprises like textile, pharmaceuticals and chemicals, tanneries, etc. Cannot release Contaminated water without treatment as it contains toxic and non-toxic chemicals.

If it Releases in pure water, it may cause contamination of the existing pure water and affect the environment. As a result, ETP's install in most manufacturing industries is compulsory.

Effluent Treatment Plant Inquiry!

Effluent Treatment Plant

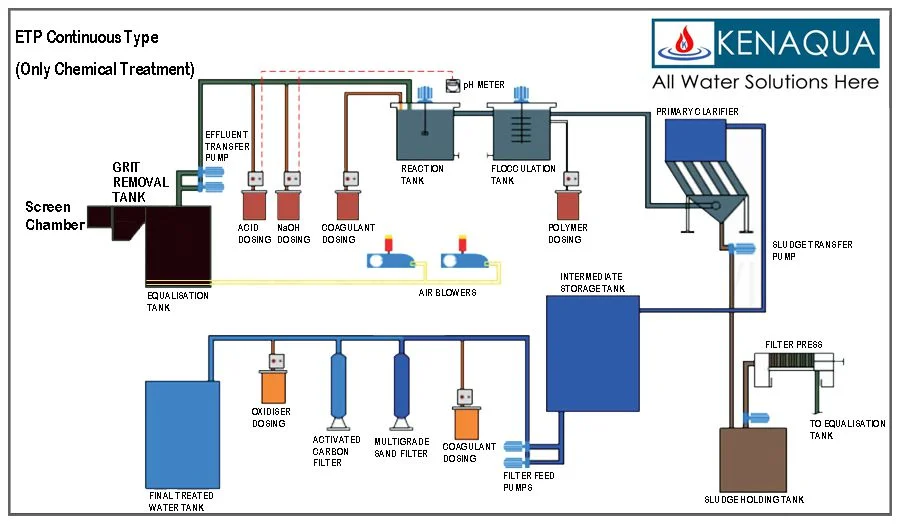

Effluent Treatment flow sheet diagram: ETP Continuous Type

- Screen Chamber:

- The screen chamber removes almost large solid to bypass the abrasion of mechanical devices and clogging of the hydraulic system.

- Collection Tank:

- The collection tank obtains the effluent water from the screening chamber, stores and then pumps it to the equalization tank.

- Equalization Tank:

- The effluent does not have a similar concentration at all the time; the pH will vary.

- Effluents store for 8 to 12 hours in an equalization tank. They are resulting in the homogenous mixing of effluents and helping in neutralization.

- Continuous mixing also eliminates the settling of solids within the equalization tank.

- Reduce Suspended Solids(SS) and Total Suspended solids (TSS) into the water.

- Flash mixer: Coagulants added to the effluents.

- Lime:(800-1000 ppm) To correct the pH upto8-9

- Alum: (200-300 ppm) To remove color.

- Polyelectrolyte: ( 0.2 ppm) to settle the suspended matters into the water, and reduce SS, TSS.

- Clarriflocculator:

- In the Clarriflocculator, the water is circled continuously by a stirrer.

- Flocculation gives delayed mixing that starts to macro flocs, which next settles in the clarifier zone.

- Overflowing water operates out to the aeration container.

- The solid particles settle down and are collected separately; this reduces SS, TSS.

- The settled solids, i.e., primary sludge, are pumped into sludge drying beds.

- Aeration Tank:

- The effluent, after clarification, runs to an aeration container for aerobic treatment.

- This container is implementing with air blowers or diffusers applying which air is passing through the tank.

- This air is needed to sustain the aspired dissolved oxygen (DO) level required for bacteria to improve and remove BOD and COD by splitting down the matter.

- BOD and COD values of effluent are reducing up to 90%.

- Secondary Clarifier:

- Overflow from aeration tank to the secondary tank where solid-liquid separation occurs.

- The solid inhabited in secondary clarifiers is called organic sludge, which is recycled back into the aeration tank to maintain the desired MLSS level.

- The outlet water quality is checking if it's within the accepted.

- The treated water is disposing of through pipelines.

- Sludge Thickener:

- The inlet sludge consists of 60% water + 40% solids.

- The effluent is moving through a centrifuge.

- Due to the centrifugal action, solids and liquids dissociate.

- The sludge thickener reduces the water content in the effluent to 40% water + 60% solids.

- The effluent is then reprocessing, and the sludge is collecting at the bottom.

- Drying Beds:

- Primary and secondary sludge is dried on the drying beds to reduce the water content further.

Questionnaires for designing proper solution in Effluent Treatment Plant (ETP Plant):

| # | Description |

|---|---|

| 1 | Name of the Party with detailed Office / Factory address with the concerned person name and contact nos? |

| 2 | The site address in detail where this plant is going to Install / Operate? |

| 3 | Are you an end-user of this project? |

| 4 | What is the primary purpose of installing the system - Govt regulation / Strong need for recycling / To get PCB consent / Caring environment? |

| 5 | What is your manufacturing activity/process (Pls attach a flowsheet diagram showing wastewater generating stations)? |

| 6 | Effluent Composition (i.e., what will be the specific contents of Effluent)? |

| 7 | Approx Total quantity of Effluent generated daily? |

| 8 | New project or modifications, Please provide details about the existing system as - Pictures, Capacity, BOQ, etc. |

| 9 | Please attach a detailed effluent analysis report comprised of pH, TDS, TSS, COD, BOD, O&G, Cl, SO4, etc.? |

| 10 | Did output treat water quality expected - In terms of parameters as mentioned above? |

| 11 | Should you carry out any treatability studies for effluent? If so, please attach the report herewith. |

| 12 | Location availability - Allocated area in terms of L X W X H in Meter? |

| 13 | Types of System: Civil / Containerised / MS-Package? |

| 14 | Output Treated Water Quality in terms of TSS & BOD (Or attach specific requirement) |

| 15 | Final usage of treated Water - Gardening / Toilet Flushing? |

| 16 | Do you have your own civil construction contractor/team? |

| 17 | When are you expecting to start this project date? |

ETP Plant Technician

common effluent treatment plant